FRAMES Website: Link

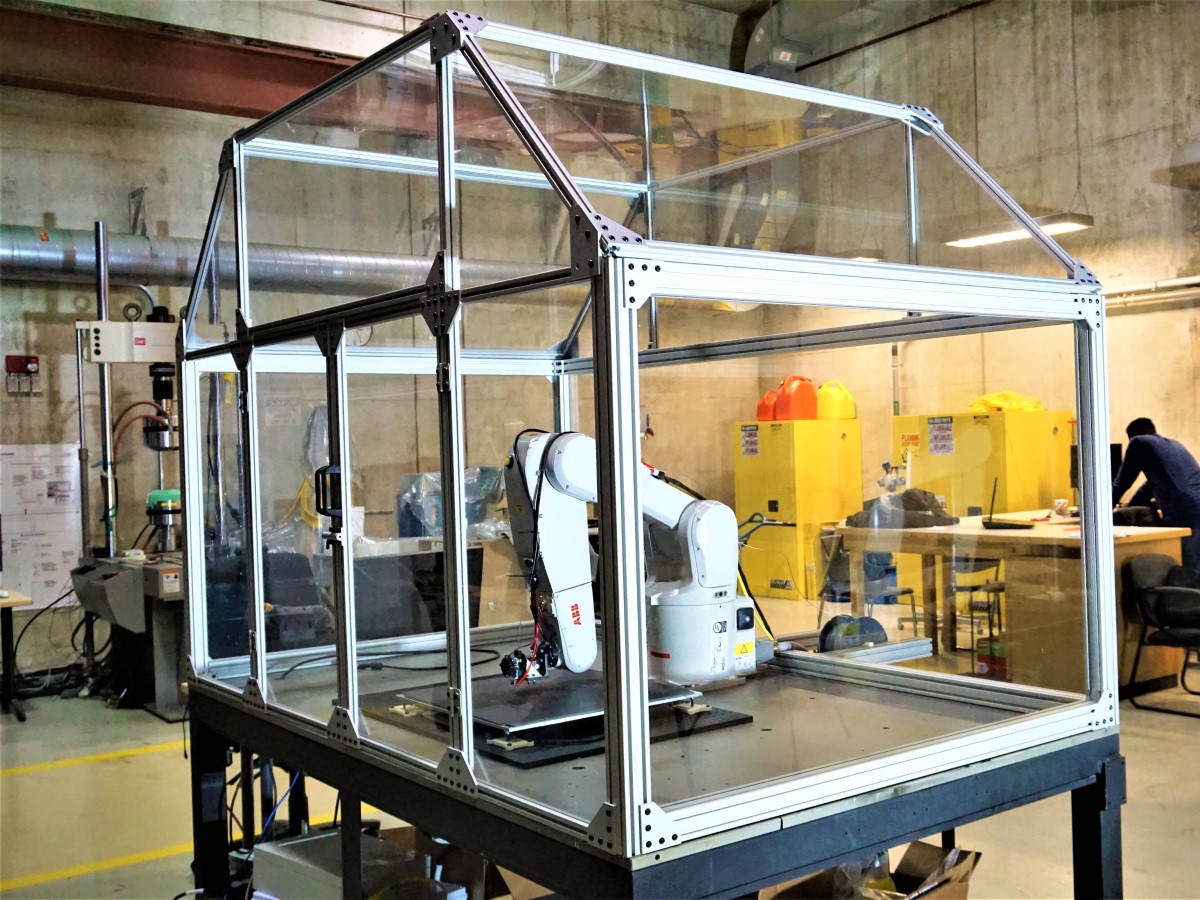

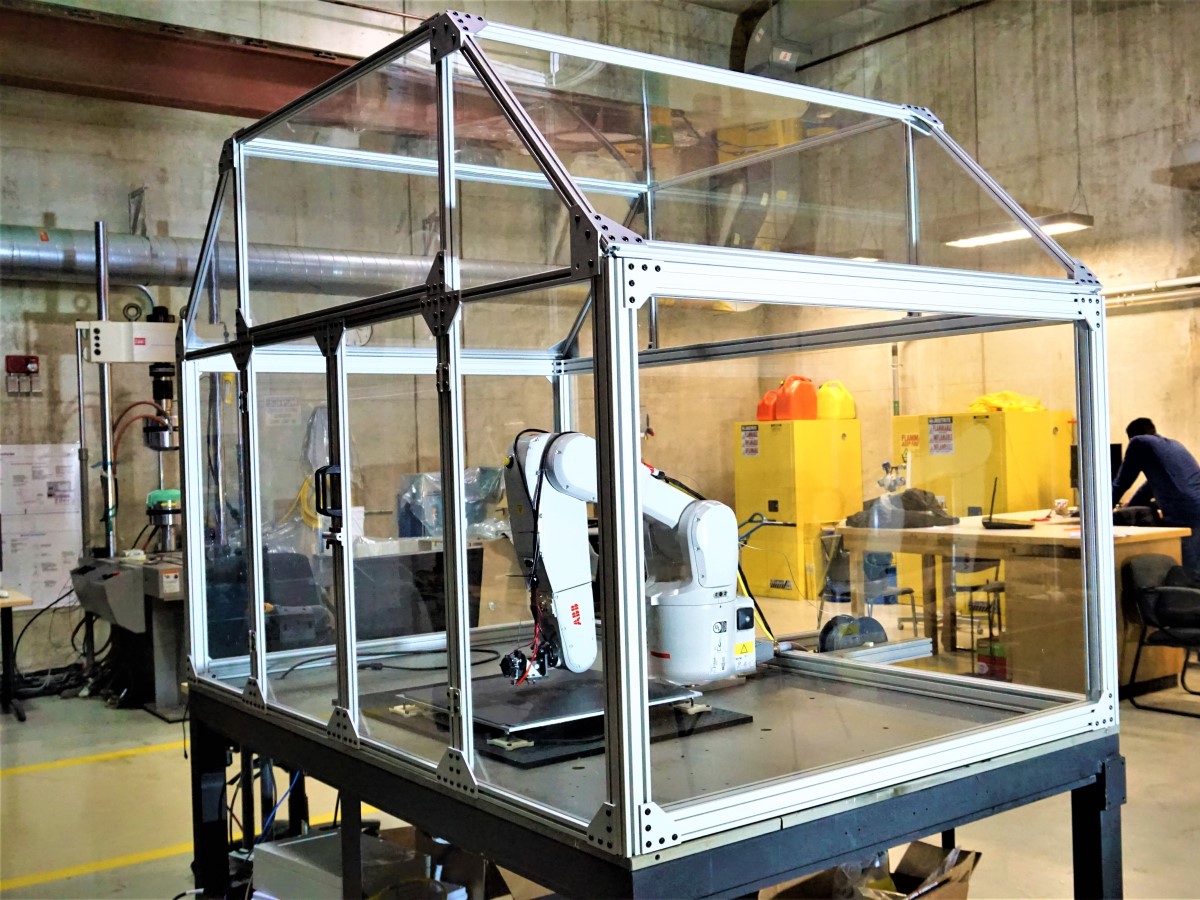

I played a pivotal role in the conversion of an industrial ABB robotic arm into a 6-degree-of-freedom (6-DOF) 3D printer capable of manufacturing parts with continuous carbon-fiber reinforcement and a PAEK matrix. This project involved integrating filament feeding, compaction, cutting, and bed heating systems to enable the production of complex geometries with high-performance materials.

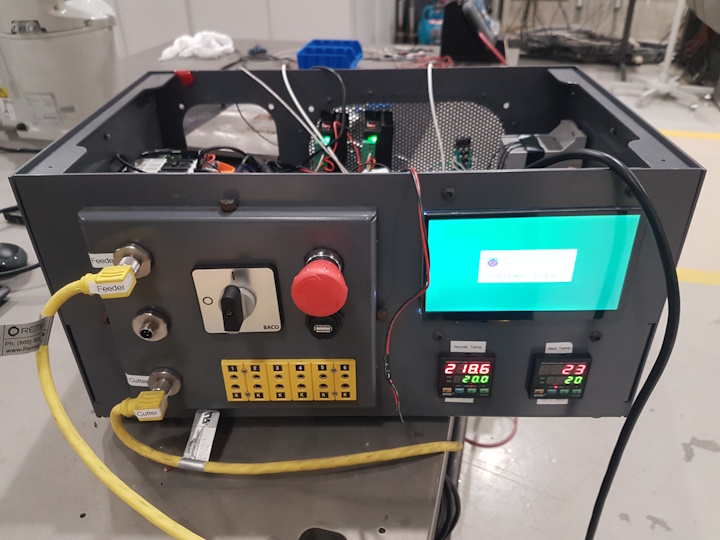

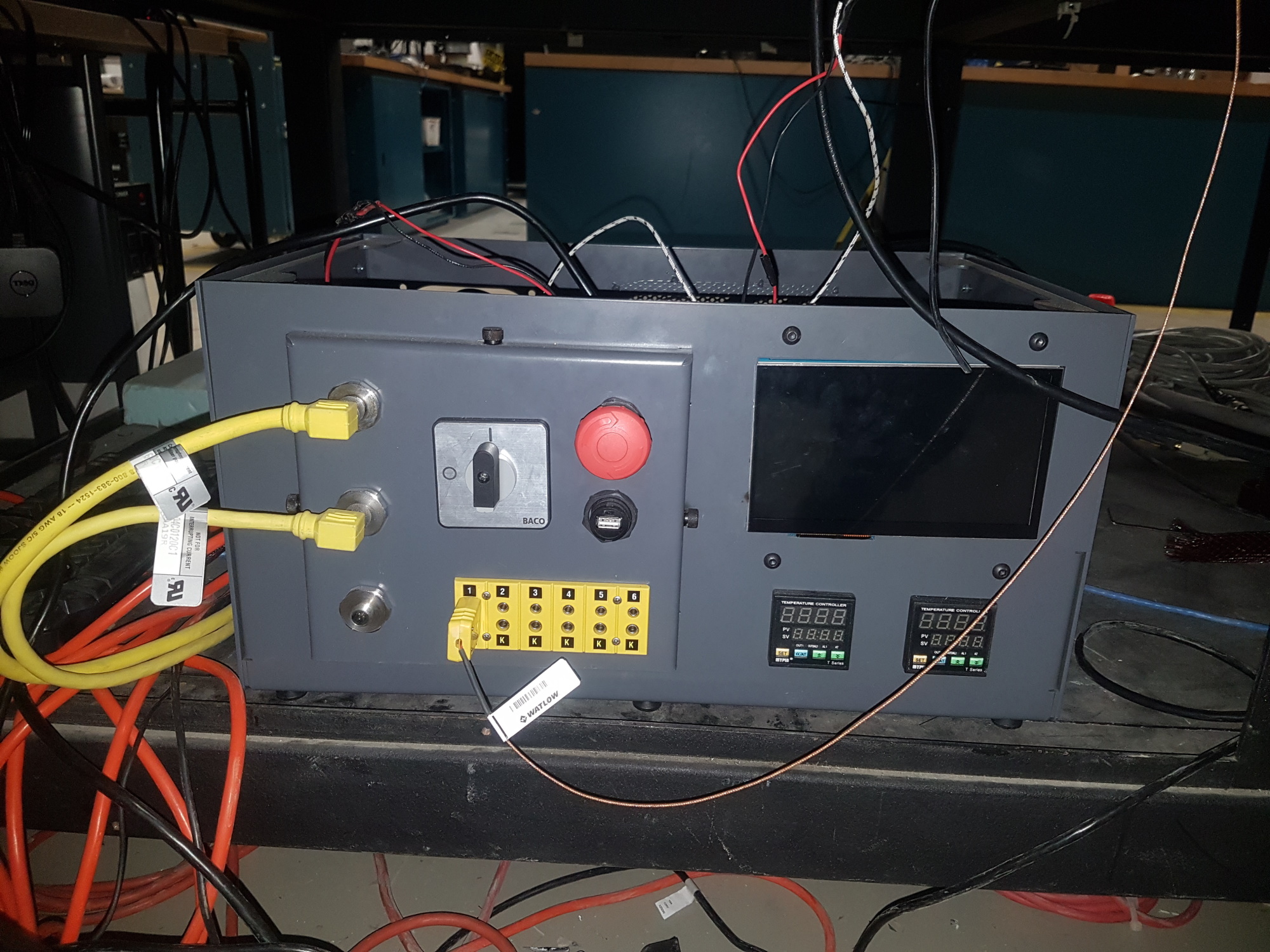

I designed and implemented a Programmable Logic Controller (PLC) using a KUNBUS Revolution Pi to manage the 3D printing process. The PLC, programmed in Python and C++, controlled various components via serial communication and featured an 8-inch touchscreen with a custom GUI for real-time monitoring and toolhead changes.

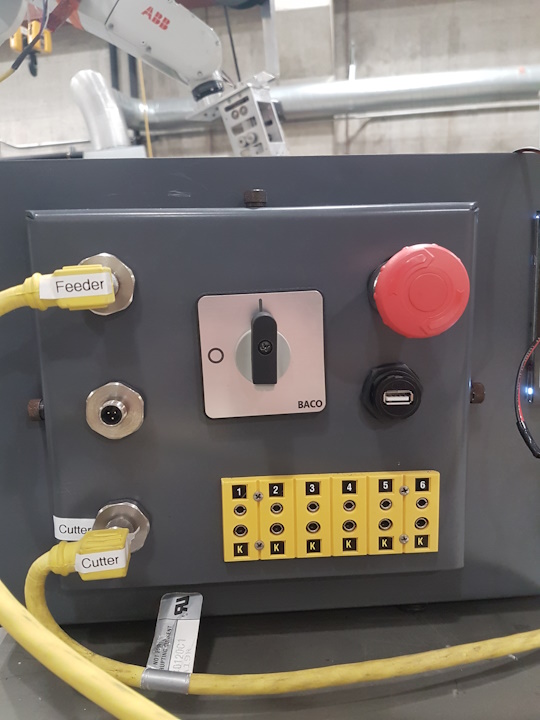

I designed a modular PLC enclosure featuring M12 connectors, a USB port, six K-type thermocouple ports, a power switch, and an emergency stop button. The enclosure’s replaceable component panel and DIN rail mounting system allowed for easy upgrades and modifications as the project evolved.

I developed and tested a pneumatic system for semi-automated toolhead changes on the 3D printer. This system improved operational efficiency and reduced downtime, showcasing my ability to integrate mechanical and control systems for enhanced functionality.

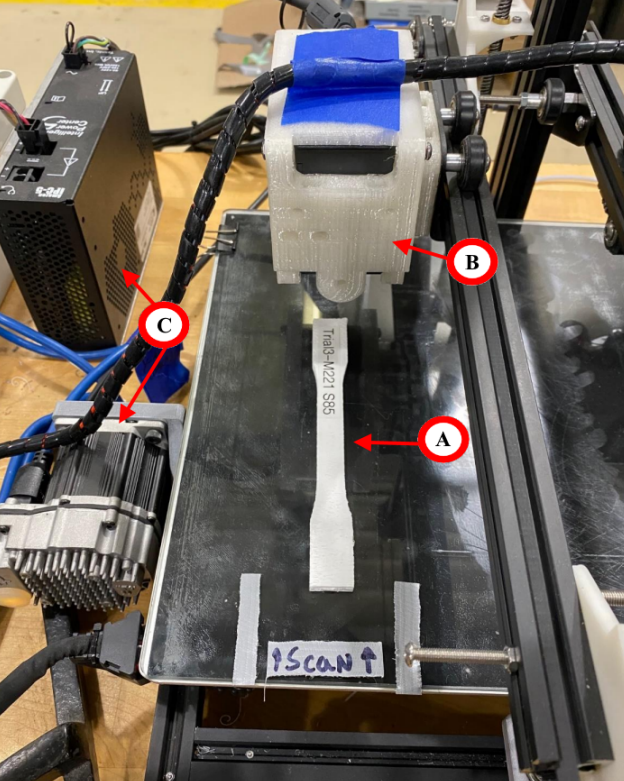

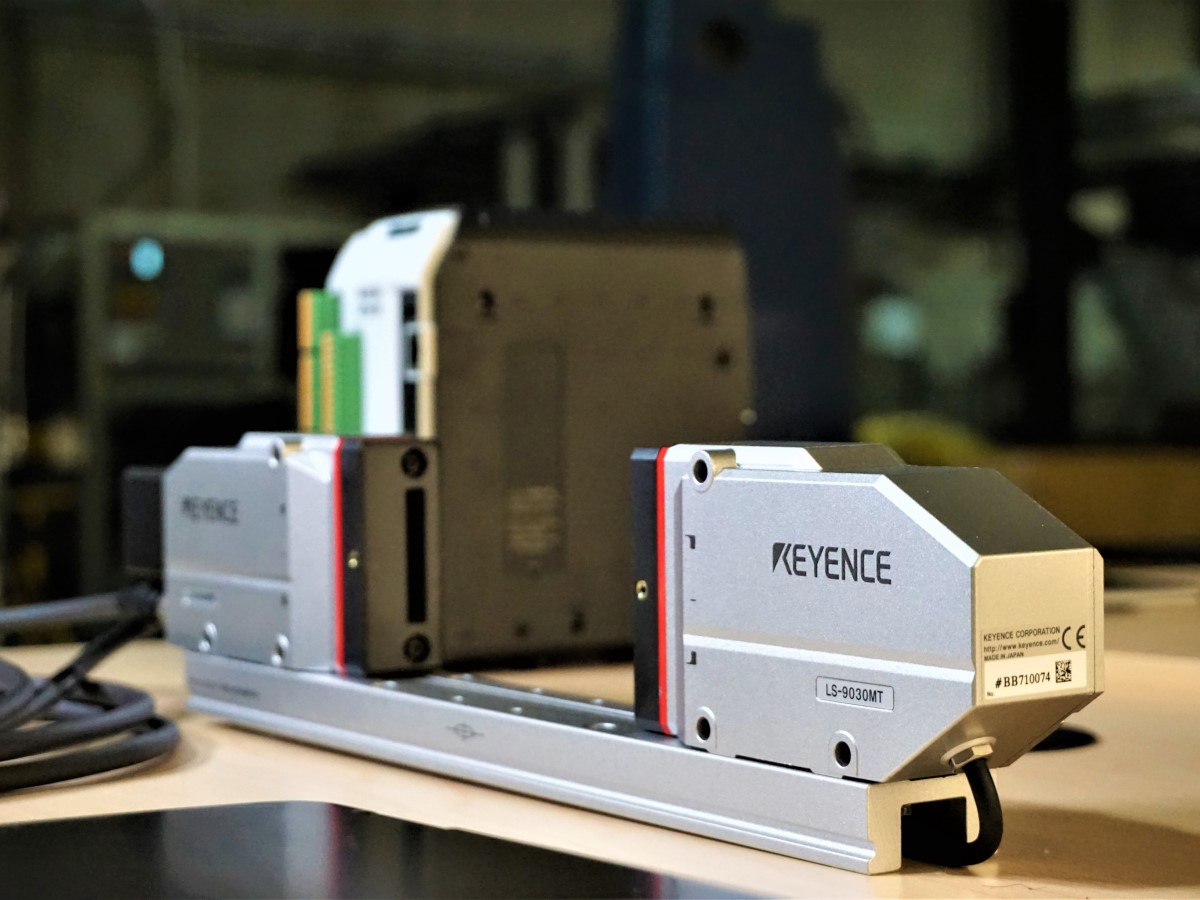

I integrated a Keyence LJ-V7080 laser line scanner into the 3D printing system for in-situ inspection of manufactured parts. The scanner, mounted on a custom 3D-printed fixture, provided real-time defect detection and quality assurance during the printing process.

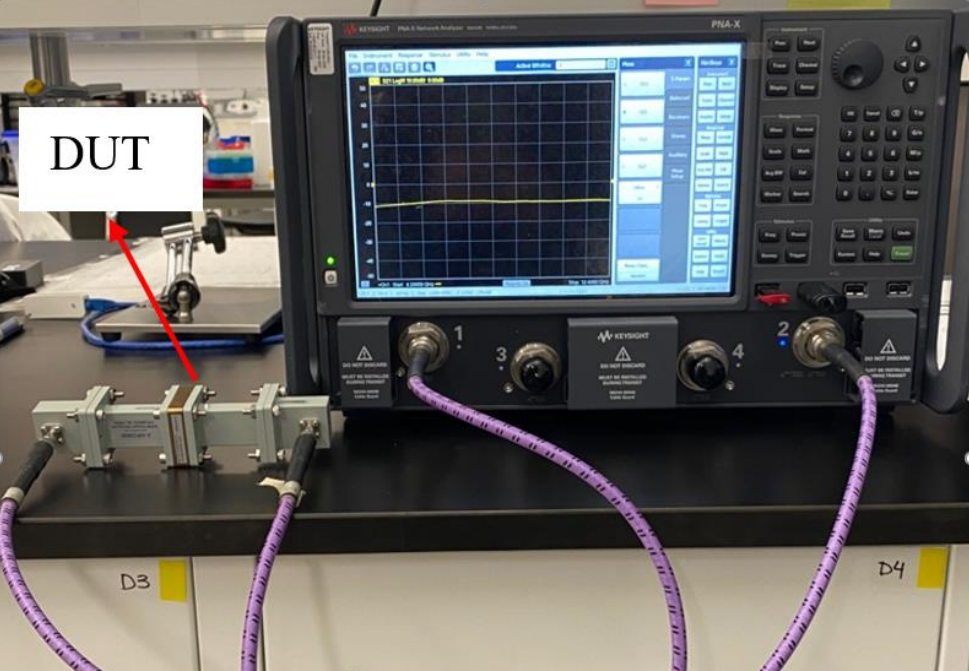

Test apparatus for defect scanning, featuring:

A: D638 test coupon.

B: Keyence LJ-V7080 laser line scanner.

C: Closed-loop motor and driver.

This setup enabled precise defect detection and analysis, ensuring high-quality part production.

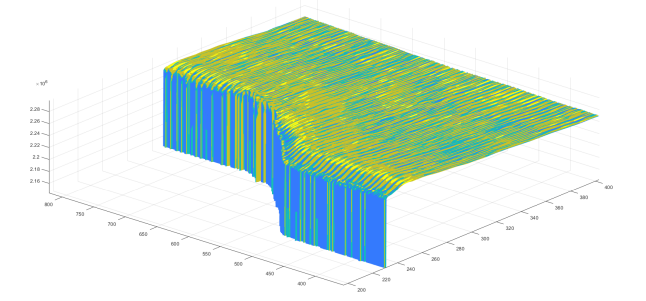

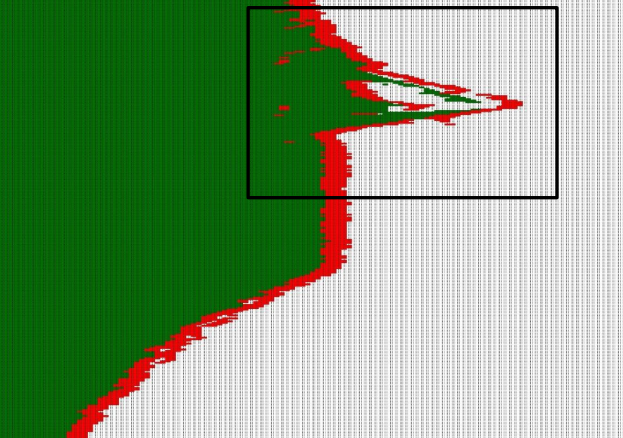

Processed and analyzed data from the Keyence LJ-V7080 laser line scanner to generate 3D renderings of scanned parts. This allowed for detailed inspection of D638 test coupons and identification of manufacturing defects.

Using layer-by-layer analysis of scanned data, I identified defects such as voids, layer shifting, and under/over extrusion. This analysis informed process improvements and ensured consistent part quality.

A Keyence LS-9030M laser micrometer was used to measure filament diameter during the extrusion of recycled PLA pellets. This system ensured precise material deposition and improved print quality.

I was responsible for the upgrade and maintenance of a custom 3D printer with a heated chamber for high-performance thermoplastics. This printer enabled the production of parts with enhanced mechanical properties and dimensional accuracy.